Big Discount Hydraulic Expansion Joint - A-5 ~Threaded Union – Lide

Big Discount Hydraulic Expansion Joint - A-5 ~Threaded Union – Lide Detail:

Details

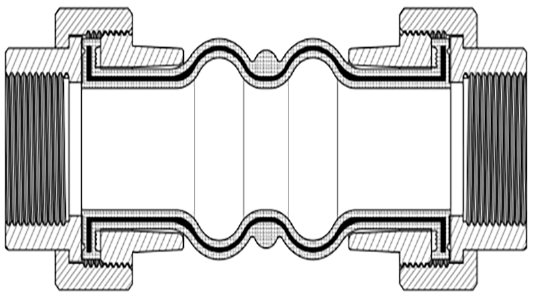

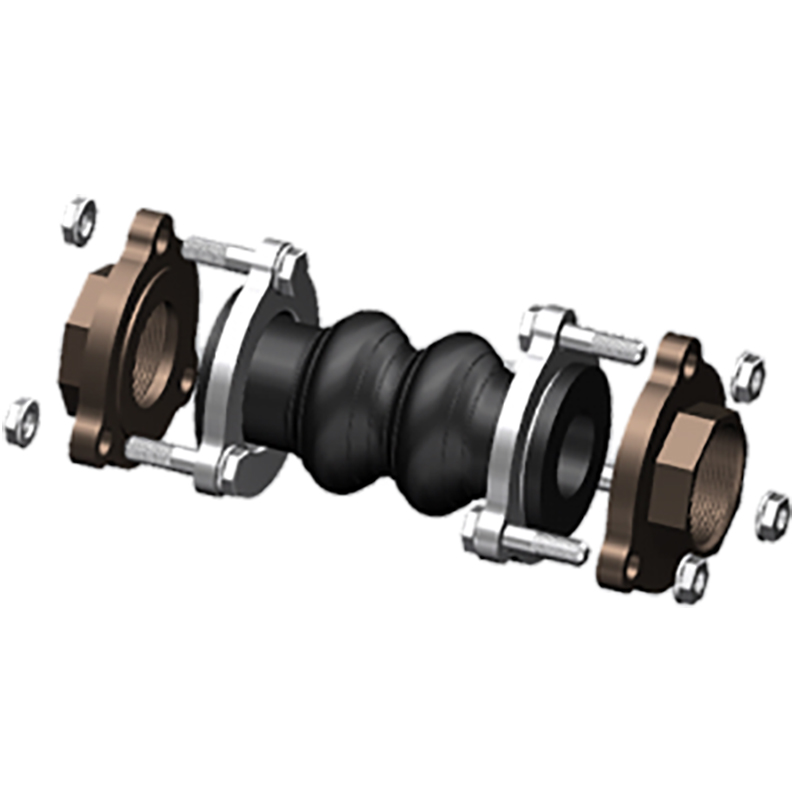

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI.

| Specifications | II | ||

| Working Pressure Mpa (Kgf/Cm2) | 1.6 (16) | ||

| Test Pressure | 2.4Mpa | ||

| Burst Pressure Mpa (Kgf/Cm2) | 4.8 (48) | ||

| Vacuum Kpa (Kgf/Cm2) | 86(660) | ||

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN80 | ||

| Connection Method | THREAD | ||

| Flanges Dimensions | BS, ANSI | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | THREAD | ||

| Flange Material: | MALLEABLE IRON, DUCTILE IRON | ||

| Period of Delivery | about 21 working days | ||

|

Threaded Union (TU) |

||||||||||||||

|

SIZE |

OAL Length |

Allowable Movement-1 |

Dimensions |

Operating Conditions |

||||||||||

|

Nominal Diameter |

Neutral OAL |

Min Installed |

Max Installed |

Max Compressed |

Max Extended |

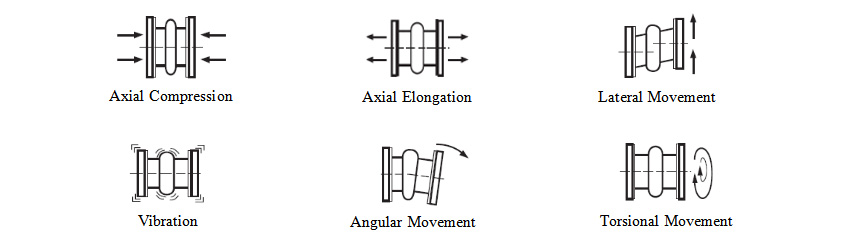

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

OAL Fitting |

OAL Body |

Max w.p. (bar) |

Max Vacuum (in. of Hg)-4 |

|

|

Inch |

mm |

|||||||||||||

|

1/2″ |

15 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

0.92″ |

6.16″ |

150 |

26″ |

|

3/4″ |

20 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

1.00″ |

6.00″ |

150 |

26″ |

|

1″ |

25 |

8” |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±25.3° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/4″ |

32 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±20.7° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/2″ |

40 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±17.5° |

1.35″ |

5.30″ |

150 |

26″ |

|

2″ |

50 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±13.3° |

1.60″ |

4.80″ |

150 |

26″ |

|

2-1/2″ |

65 |

9.6″ |

8.95″ |

9.72″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±10.7° |

2.00″ |

5.60″ |

150 |

26″ |

|

3″ |

80 |

9.6″ |

8.95″ |

9.72′ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±8.9° |

2.00″ |

5.60″ |

150 |

26″ |

|

Threaded Union (TU)-Jis Standard |

||||||||||||

|

Nominal Dia |

Nominal |

Allowable Movements (mm) |

Installation Tolerances (MM) |

OAL Fitting (MM) |

OAL Body (MM) |

|||||||

|

Inch |

mm |

Length (MM) |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

||

|

1/2 |

15 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

3/4 |

20 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 |

25 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 1/4 |

32 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

1 1/2 |

40 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

2 |

50 |

255 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

40 |

175 |

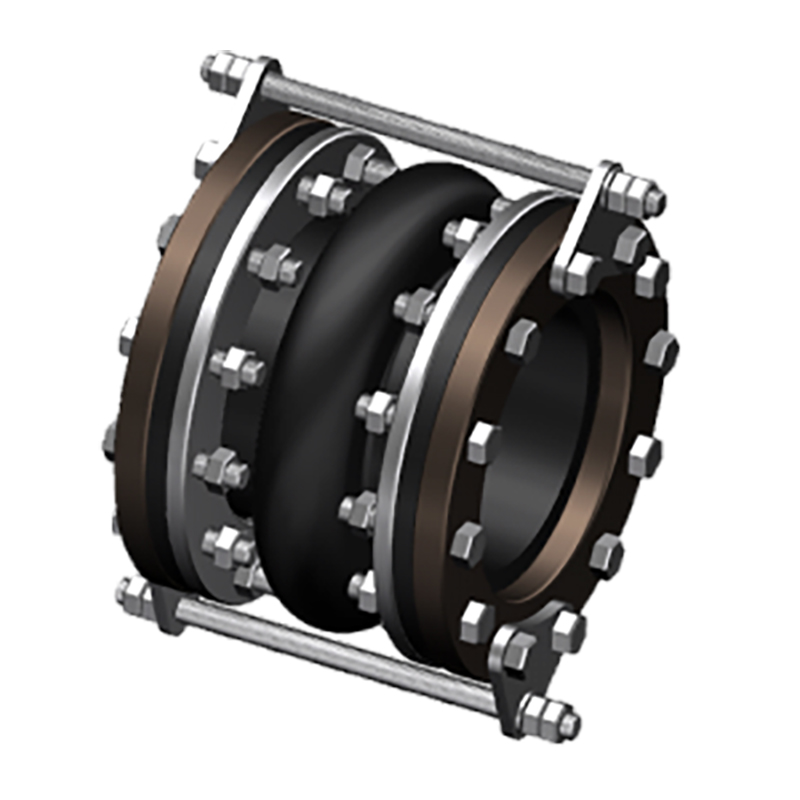

Product detail pictures:

Related Product Guide:

Big Discount Hydraulic Expansion Joint - A-5 ~Threaded Union – Lide , The product will supply to all over the world, such as: , , ,

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang