Top Suppliers Double Wave Epdm Rubber Joints - Abrasion resistance rubber expansion joints – Lide

Top Suppliers Double Wave Epdm Rubber Joints - Abrasion resistance rubber expansion joints – Lide Detail:

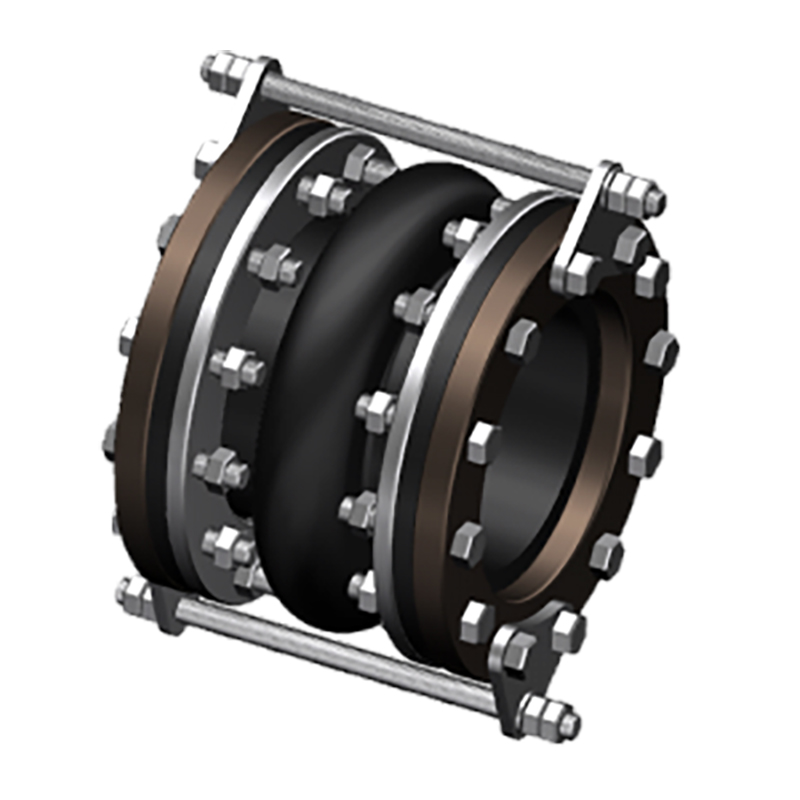

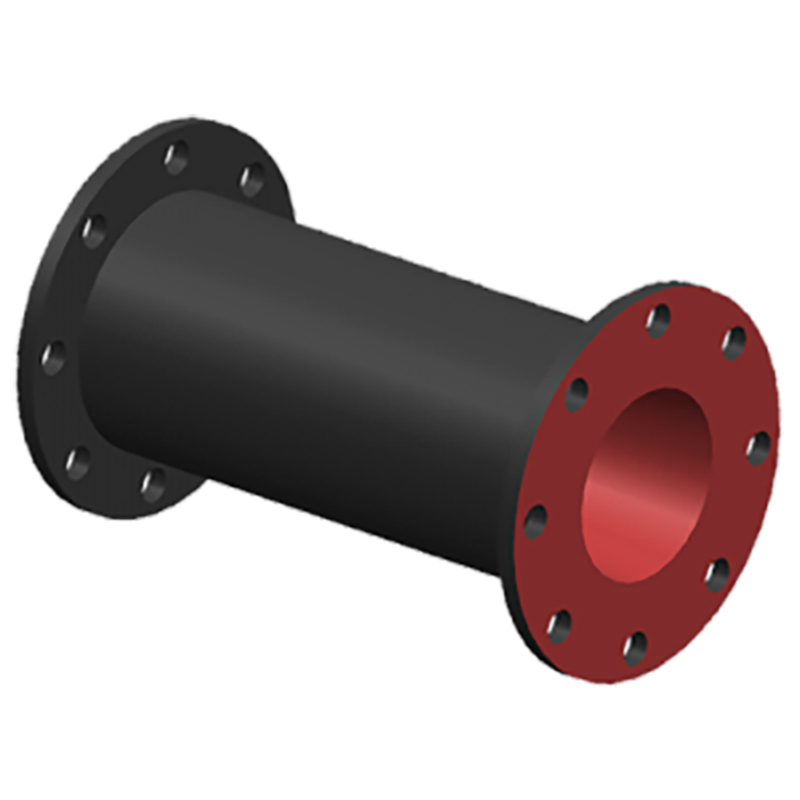

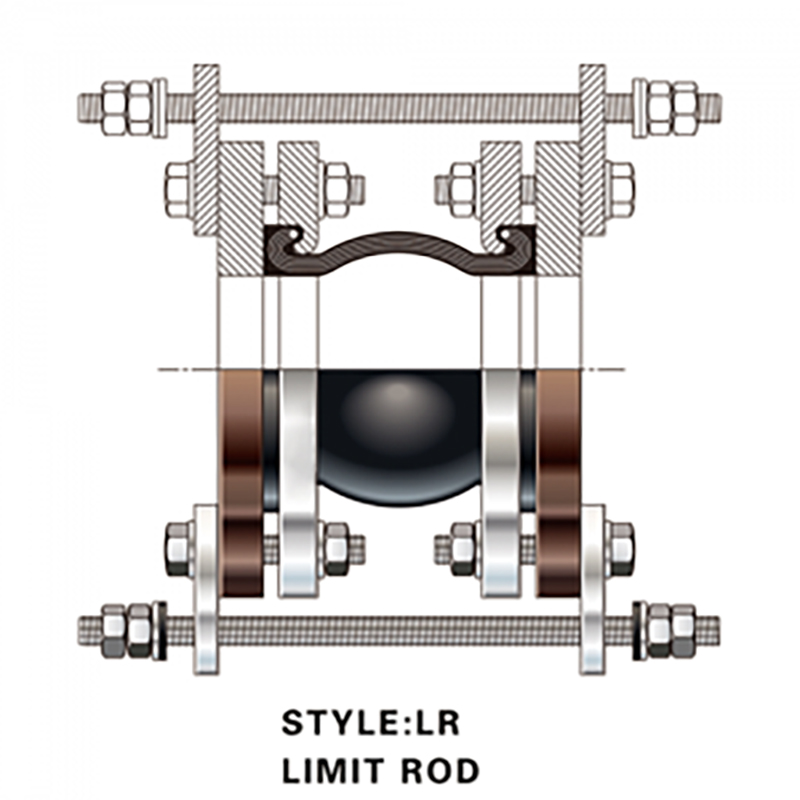

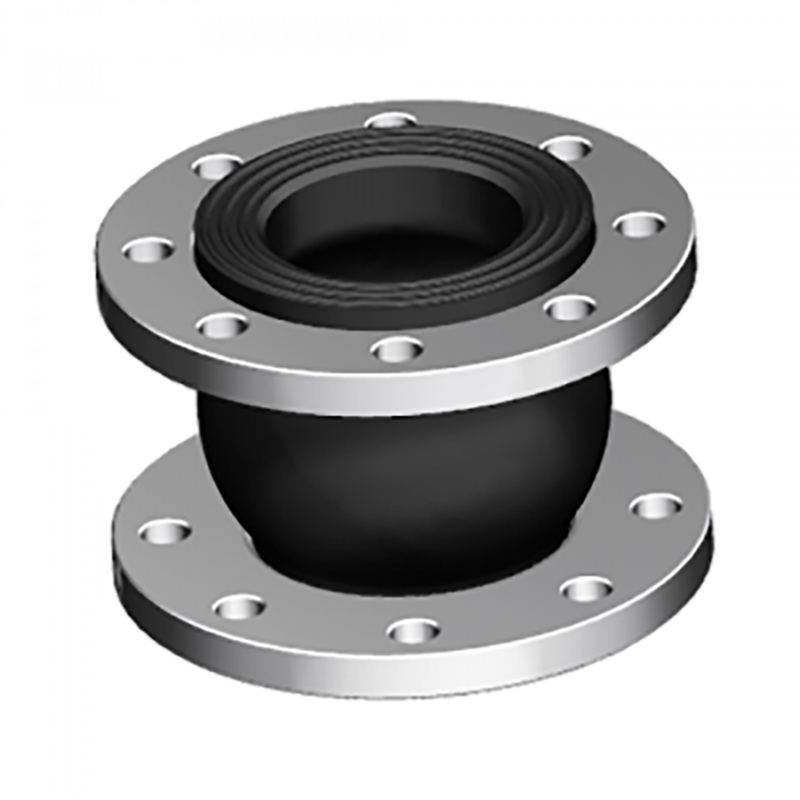

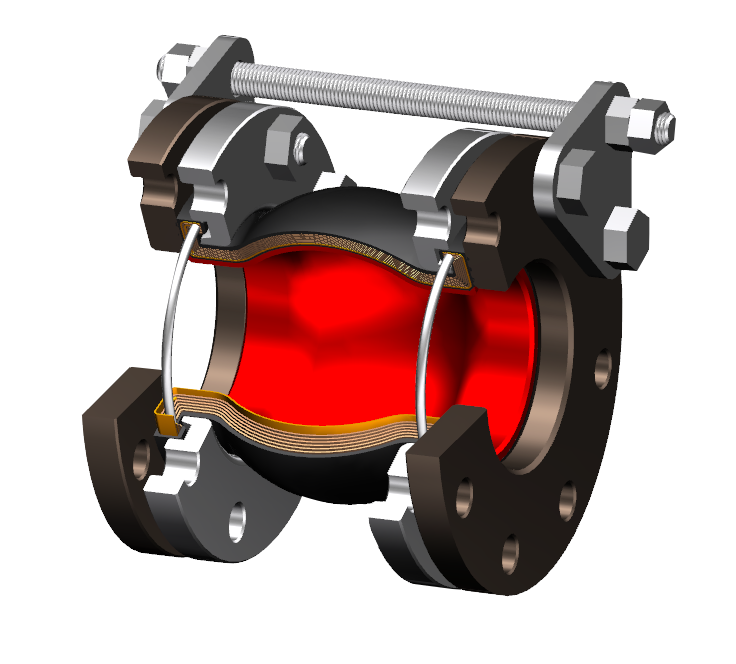

Expansion rubber joints are assembled on the piping, which can reduce the vibration, reduce noise, protect pipe system from start-up forces as well as system surges, compensate movements and misalignments from the piping line.

The rubber joints are used below systems, but not limited

Commercial HVAC systems

Industrial piping systems

Power plants

Sewage treatment plants

The material of tube is reinforced natural rubber, which can increase the abrasion resistance, worn-resistance. This rubber material can be used in fluid media, which include grit, such as slurry, pulp, ash slurry, mining industrial.

The reinforced middle layer is impregnated with nylon tire cords, which can increase the flexibility and stiffness.

The rubber material of outer cover is used based on working conditions, such as UV resistance, acid-resistance, or alkali resistance.

Our Process Quality Control

We treasure process quality control, there is very strict operation specification each process, which can ensure the goods quality:

1. We use electronic weigher to weigh the weight of ingredients, the precision of weight is gram. So there is no surplus compounds elements;

2. 1.) By controlling material temperature and mixing time in the mixer machine, we can get qualified rubber mixed composites.

2) The calender process is the more critical phase, large steel rollers force rubber composites into smooth rubber sheets.

3)The rubber sheets produced every day must be finished within the same day, we can ensure no rubber sheet remainder each day.

4) All rubber sheets have passed the test of curometer.

3. Adding adhesion agent in the mixture of rubber and nylon tire cord, then the rubber and nylon tire cord can be adhered together and turn into the integral. After vulcanization, all the rubbers are adhered tightly, it is very difficult to delaminate.

Below is the pictures of plastic sheet combined with rubber and nylon tire cord:

4. In wrapping process: all the elastomer constructions are made by hand-built and machine. After hand-builting, the underneath pressing roller moves along the elastomer body and compact the rubber sheets. There are two main functions of the roller, one is compacting the rubber sheets and making the rubber sheets more bonded, the other one is extruding air between rubber films. So it is very difficult to generate blisters and delaminate after vulcanizatio

5. After vulcanization, there are 4 inspection processes: first qualified products inspection, trimming, assembling process, inspection for finished goods, if the goods with blisters are found then scrap.

6. Our company has 10 years of production experiences, and the products are exported to Colombia, Hongkong, Germany, Singapore, Vietnam, Turkey, Egypt, Italy, US. Our goods has gained very good reputation.

Miscellaneous Tests:

1. Movement tests including lateral, Axial, Angular movements

i) Samples: the rubber joints 24 hours at least after vulcanization

ii) Equipments: electrical hydraulic test pump or manual hydraulic test pump

Pressure meters

Test platform

iii) Media: water

iv) Increasing pressure rate: it is usually 0.075Ma/S -0.175Mpa/s, and the test pressure does not exceed 7Mpa. If 7Mpa can not be met, both parties can decide a specified pressure.

v) Preparation: Assemble the flange cover with discharging valve on one end of rubber joints, it is free end.

Assemble flat flange cover and hydraulic pump discharging pipe, then fix them on the platform.

Let water running into the rubber joint with lower pressure and let the air running out of the rubber joint. Turn off the discharging valve and stop the pump.

Adjust the axis and fix the free end. Measure the parallel axis and take down the record of original length.

vi) Axial movement tests: after all-above mentioned are done, enlarge or compress with the allowed maximum enlongation length or minimum compression length. Fix the rubber joints, increase the pressure till to working pressure, keep 10 minutes, check the rubber joint if there are leakage, cracking or deformation.

Product detail pictures:

Related Product Guide:

Top Suppliers Double Wave Epdm Rubber Joints - Abrasion resistance rubber expansion joints – Lide , The product will supply to all over the world, such as: , , ,

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang